ALPHAPLATRE Our scope of activity

Blocks

The gypsum blocks are small building items – 3 per m² – designed for the building of partition walls. The tongues and grooves moulded on the edges make the assembly easy, quick and robust. The perfect flatness of the gypsum blocks also enables to avoid using coatings.

Alphaplatre was originally specialised in the design and installation of gypsum blocks units and, over the years, has developed various processes and solutions responding to the demand of each customer.

Process Description

The plaster and water are weighed and introduced in a mixing tank. After few minutes of blending, the mixing tank rotates to pour the mixture into the Gypsum Blocks machine. This machine guarantees the dimensional characteristics and the perfect flatness. Blocks are then extruded and placed on wagons in order to get dried.

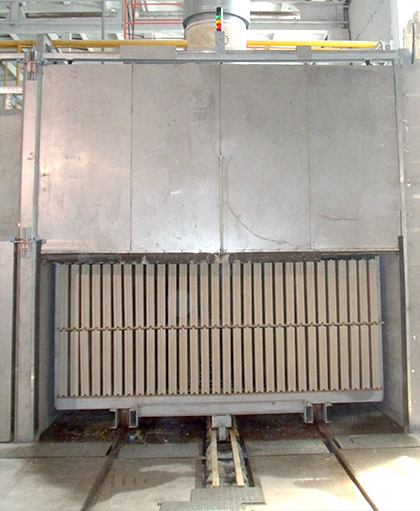

The drying of gypsum blocks is a key step as it gives them the resistance and hardness. The artificial drying is processed in a tunnel in which blocks are in contact with hot air supplied by ventilating fans set straight beside and upstream the gas burners. The air sweeps the gypsum blocks on a constant and homogeneous basis. Alphaplatre has developed several drying solutions in order to answer to its customers’ demands.

- Longitudinal drying

- Transversal drying

- Drying with condensers

Production capacity

| Thickness of the blocks | Minimum (m²/y) | Maximum (m²/y) |

| 50 mm | 315 000 | 525 000 |

| 60 mm | 252 000 | 420 000 |

| 70 mm | 220 000 | 367 500 |

| 80 mm | 189 000 | 315 000 |

| 100 mm | 157 500 | 262 500 |

This type of units operates 24/7. The complete cycle is automated and guarantees an average capacity of 6 extrusions per hour.

Advantages of our solution

- A complete range of products – Alphaplatre can provide production units for blocks of all thicknesses and to the specific needs of any building requirements.

- A recognised know-how – Initially specialised in this process, Alphaplatre has a perfect knowledge of this solution.

- Manufacturing control – Thanks to our workshops in France and abroad we manufacture the main equipment ourselves ensuring reactivity, quality and reliability.

- Financial optimisation – Our solutions are designed to reduce your initial investment while ensuring a high quality production.