ALPHAPLATRE Our scope of activity

Boards

Gypsum boards are building items of various sizes used in the construction of partition walls and ceilings. Assembly is done on metallic or wooden structures. Gypsum boards are much more technical products than gypsum blocks. However, their manufacturing process has only evolved slightly over 100 years. Nowadays, the product is completely regulated, standardised and normalised.

Alphaplatre offers advantageous solutions in various aspects meeting with customers’ needs.

Process description

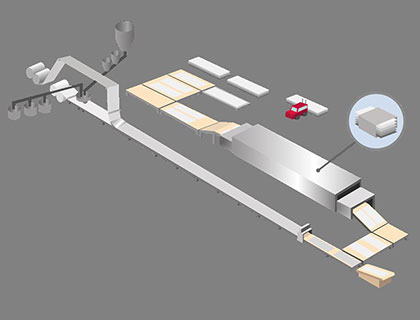

In order to manufacture gypsum boards, several products are needed to meet the requirements. Those various products are stored, weighed and then poured into a mixer before being discharged on the forming plate. This mixture is then recovered by the ivory and white paper and forms a unique long board. At the end of the forming line an automatic cutting is performed to obtain boards at the required length.

The boards are then turned over and fed into the dryer, which plays an essential role. At the dryer exit boards are stacked by pairs with the ivory side face to face ready to be recut at the exact dimensions before being palletised.

Production capacity

| Speed m/min | m²/min | Capacity m²/h | m²/year |

| 10 | 12 | 720 | 5 200 000 |

| 15 | 18 | 1 080 | 7 800 000 |

| 20 | 24 | 1 440 | 10 400 000 |

| 25 | 30 | 1 800 | 13 000 000 |

| 30 | 36 | 2 160 | 15 600 000 |

| 35 | 42 | 2 520 | 18 200 000 |

| 40 | 48 | 2 880 | 20 800 000 |

| 45 | 54 | 3 600 | 23 400 000 |

Hypothesis:

- Reference product : Tapered edge board ( 2400 x 1200 x 12.5 mm)

- Efficiency : We estimate a global machine efficiency of 91%

- 330 working days / year

Advantages of our solution

- Manufacturing control – Thanks to our workshops in France and abroad we manufacture the main equipment ourselves ensuring reactivity, quality and reliability.

- A reduced installation time – Our solution offers pre-assembled and pre tested elements shipped in containers. These pre-assembled elements are then installed on site. With this solution, we estimate a saving of 60% on the installation time

- Financial optimisation – Our solutions are designed to reduce your initial investment while ensuring a high production quality.